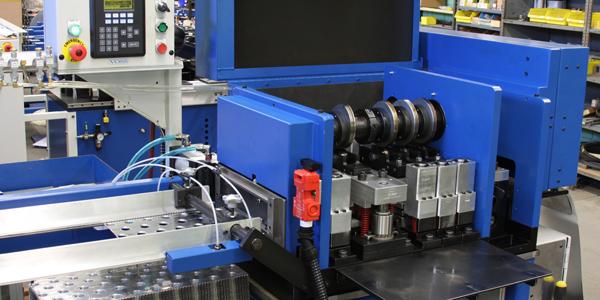

Voss produces fin machinery for round tube fins such as this FM-235-RT Machine.

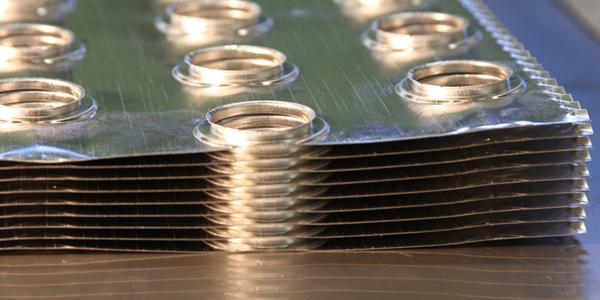

Unlike the typical drawn cup type tooling, this tooling uses a simplified version to produce the fin collar. Just a pierced hole, then flanged, with a small re-flare is what’s used to produce the fin, keeping the tooling costs down. This process allows manufacturers to get into this marketplace with less investment or prototype new fins with lower tooling costs. The machine is based on the FM-235 flat fin machine except for the feed station, which is moved over to allow more stations needed to produce the fin. This allows for enhancements such as waves, louvers, or dimples to be used in conjunction with the tube collar tooling.

Industrial Round Tube Fin Machine (FM-235-RT)

Specification

- Machine Size – 12ft [3.65m] L x 4.5ft [1.4m] W x 5.2ft [1.6m] H

- Machine Weight – 2000 lb. [900 kg]

- Machine Speed – 200 strokes per minute

- Servo feed multi pitch capability

- Pneumatic Service – 90 psi, clean, dry air

- Electric Service – US Standard – 460V/480V AC, 3 phase, 60 Hz, 20 Amp

- Other electrical services are available.

Capacity

- Max Fin Width – 10” [250mm]

- Max Fin Length – 60” [1600mm] with Standard Boom Assembly

- Max Fin Thickness – 0.010” [0.25mm] Tooling Related