Custom-engineered Solutions That Meet Your Highest Standards

Voss Manufacturing is a leader in the manufacturing industry and is your “one stop shop” for all your engineering manufacturing solutions for your one-of-a-kind prototypes up to your production runs. With our unique combination of capabilities all under one roof, Voss can be incredibly reactive to our customers’ demands. At Voss we invest in state-of-the-art technology, and most importantly, combine it with world class talent; our team drives this technology through their ingenuity to develop cutting-edge solutions to your most challenging manufacturing needs.

Core values and a can-do attitude have allowed us to seize opportunities as we diversify our capabilities. If a customer wants to lean on us for something we can provide but don’t currently, we don’t say no.

OUR SERVICES

We Deliver With Cutting-Edge Technology & Expert Craftsmanship

Partner with us for innovative manufacturing solutions tailored to your exact specifications. We deliver worldwide.

Fabrication

Voss offers high quality fabricated parts through the use of modern and innovated technology and equipment with a highly skilled versatile staff. We are able to provide solutions for one of a kind prototypes to high production runs with our vast manufacturing capabilities and expertise.

With our turret CNC 25T punch press we offer a versatile and cost-effective machine that can accomplish many tasks. With our vast list of tooling we are able to create simple formed features such as cutouts, dimples and louvers along with providing a scratch-free part. We typically punch materials such as; cold rolled or hot rolled steel, stainless steel, aluminum, brass, and copper. With the programmable feature of part nesting which allows maximum material utilization, our CNC punch press is perfect for your small or high volume parts.

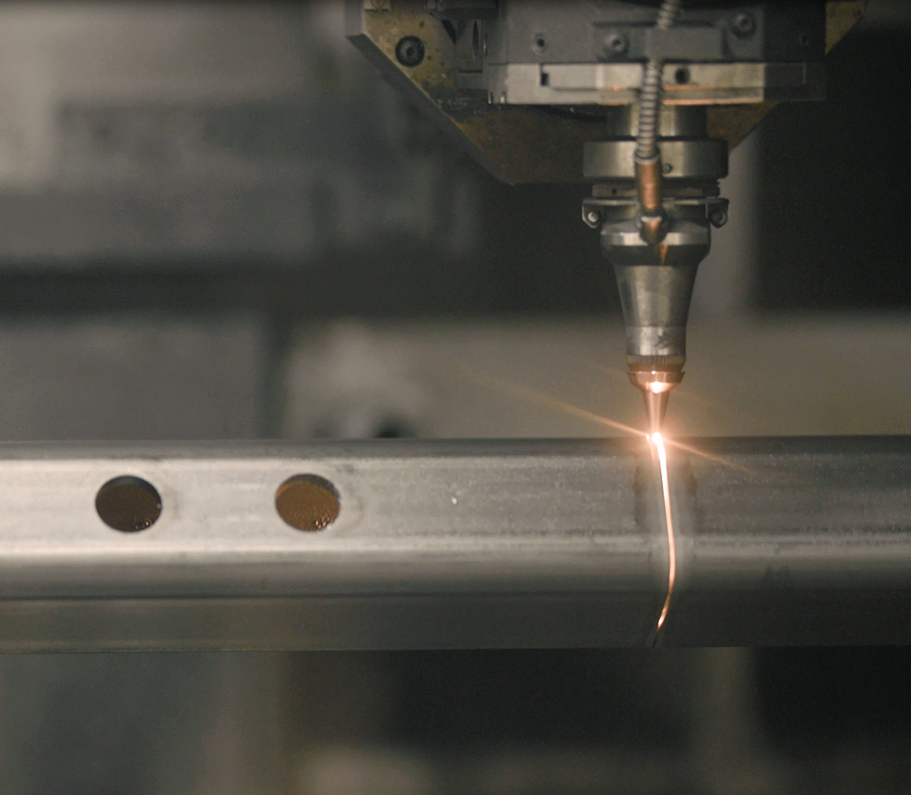

A tube laser allows us to cut metal (steel, stainless steel and aluminum) on a multi-axis basis where the material is rotated by a large chuck and the laser cuts all the necessary holes, cutouts, or profiles faster and more accurately than standard fabricating processes. The tube laser can be tooled up to cut all tubes (square, rectangle, and round), channel, I-beam, flat stock, and angle iron. A tube laser has many advantages including; quality, speed, efficiency, repeatability, versatility, and high volume manufacturing. Voss’ tube laser capabilities also include; etching, software for tab and unbending as well as tapping all cut components.

Voss’s flat laser machine allows for more complex shapes and profiles of sheet metal parts along with smaller diameter holes, more precise parts and a higher quality edge. With a large table and dual pallets our operator is able to unload parts and reload material on one pallet while the laser continues to cut on the other thus increasing our throughput and efficiency. The versatility of the laser allows us to cut material thin and thick materials such as shim stock, steel, aluminum, and stainless steel. As with our CNC punch press the programmable feature of part nesting allows maximum material utilization, thus making our laser perfect for small or high volume parts.

Voss has the capability to bend and form your sheet metal parts by bending or rolling at a required angle or forming a desired shape. With two CNC press brakes and highly knowledgeable and experienced brake operators we are able to form and bend simple to complex high-quality steel, aluminum or stainless steel parts. The standard maximum material thickness is roughly 1/4″ but depending on the bend angle and length we do have the capability to bend thicker materials.

With tool and die makers and designers in house Voss is your preferred choice for your stamping needs. Voss is set-up for small runs to large scale productions with punch presses ranging from 18 tons to 110 tons and running speeds ranging from 10 – 300 strokes per minute. With servo feeders, air feeders and air cushions Voss is also able to deep draw on top of standard stamping processes. Voss can simply manufacture your parts with supplied tooling or we can design, manufacture and build the required custom tooling on site.

Voss is able to weld simple fabrications to challenging complex assemblies with certified and experienced welders. Our highly skilled welders are able to produce high quality work that is aesthetically pleasing through the use of MIG, TIG, soldering and orbital methods. With a team of stainless steel welding experts we are capable to weld products for the semi-conductor, dairy and sanitary industries.

Voss is capable of satisfying all your stainless steel welding needs with a team of stainless steel welding experts along with the use of multiple orbital welding machines. Voss is adept to orbital weld most diameters and wall thicknesses. Voss is also tooled up to do full penetration purge welding and full consumption purge welding. Voss also has the ability to trim and face all tubing for preparation for welding.

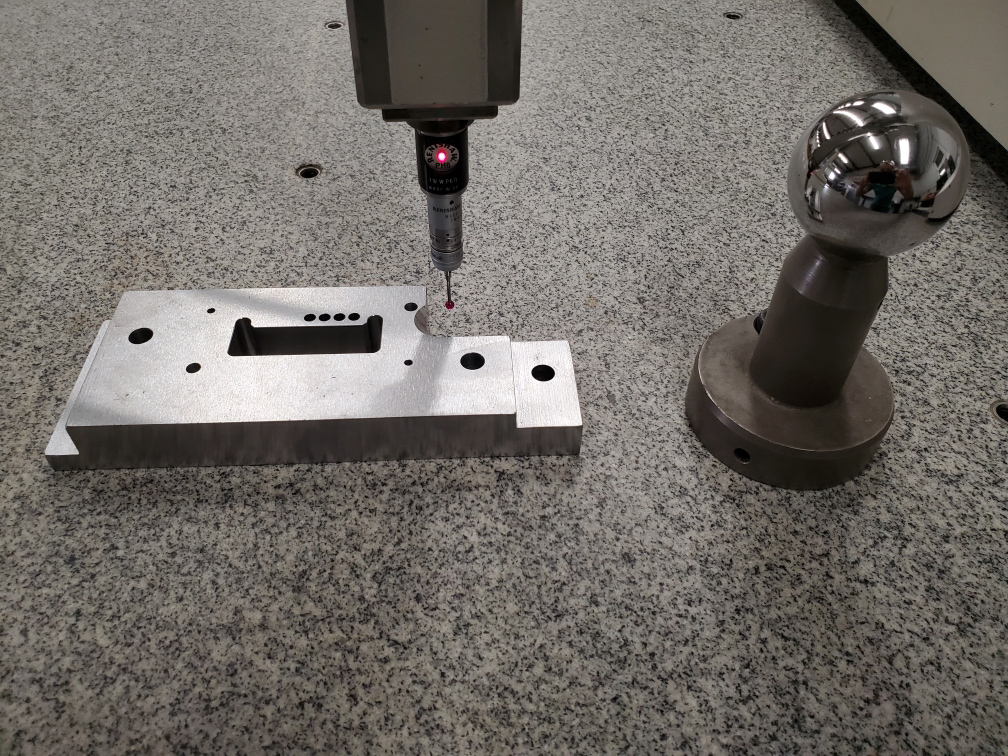

Precision Machining

Voss has a full range of machining processes in-house, offering advanced capabilities that can challenge the limits of precision and geometric intricacy. Voss has earned the ranking of an industry leader in precision machining by combining state-of-the-art machine tool technology with highly talented staff that are experts in advanced machining methods.

Voss is strategically tooled for versatility so that our machinery and staff are equipped to take on virtually any challenge and adapt quickly to the dynamic market. We handle a wide range of component complexity, from simple machined components to complex/tight tolerances. Highly flexible to handle a wide range of lot sizes – from one-off prototypes to high volume production lots – Voss is capable of machining a wide array of material types. In cases where the application demands material types that we are not yet familiar with, Voss excels in adapting and achieving high quality results.

Plastics (Delrin, Nylon, PVC, UHMW)

Aluminium (2024, 6061, 7075)

Carbon Steels (1018, A36)

Stainless Steels (303, 304, 316)

Tool Steels (A2, D2, 4140, CPM 15V) [Soft or Hardened]

While each of our machining processes individually carry a reputation of high quality and capability, we offer our customers an unparalleled advantage by being able to put them all together. Voss is your top choice one-stop shop for your machining needs. By close collaboration with our customers, we are capable to serve the unique demands of each and every customer.

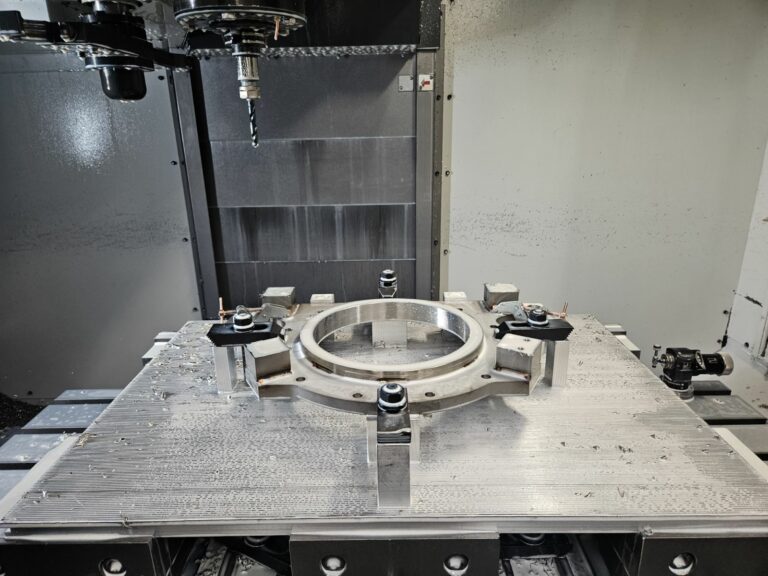

Voss offers a wide range of milling capabilities, utilizing modern CNC technology. Our machine lineup offers a wide range of work envelopes, consisting of both vertical machining centers and horizontal boring mill. Voss has multi-axis milling capability, which allows us to machine components with challenging geometry and tight feature-to-feature tolerances. Our extremely talented and creative machinists are eager to push the limits to make the impossible possible, while consistently delivering unmatched precision and quality.

Key attributes:

3-axis Vertical Mill

Max. travel (X, Y, Z): 80” x 37” x 40”

4-axis Vertical Mill

Max. travel (X, Y, Z, A): 43” x 22” x 20” x 360°

4-axis Horizontal Boring Mill

Max. travel (X, Y, Z, W, B): 98.4” x 59.1” x 57.1” x 19.7” x 360°

Loading capacity: 6,300kg (13,860 lbs.)

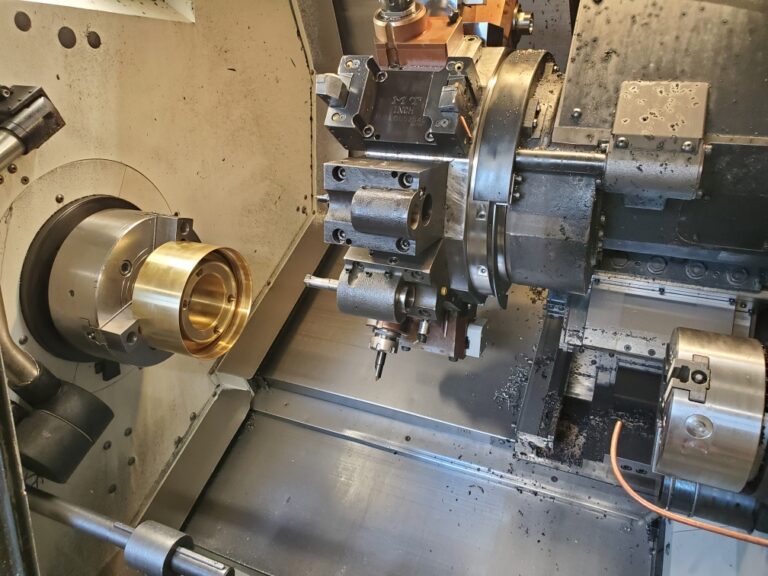

Voss offers a wide variety of turning capabilities utilizing both engine and CNC lathes. Our machine lineup offers great flexibility in processing parts, featur

ing single spindle 2-axis turning up to multi-spindle 5-axis turning center with live tooling. To increase productivity, certain turning centers are outfitted with bar feeders. Through our experience, our machinists have developed a specialization in hard turning. Maintaining a commitment to top notch talent paired with world-class technology, our turning capabilities allow us to fulfill a variety of high quality and precision turning requirements.

Key attributes:

Single–spindle 2–axis:

Max. turning diameter: 16.5”

Max. swing: 23.6”

Max. turning length: 30.7”

Max. bar capacity: 3.6”

Multi-spindle 5-axis:

Max. turning diameter: 14”

Max. swing: 36.4”

Max. turning length: 27.7”

Max. bar capacity: 3.1”

Voss offers surface grinding for applications that require greater precision or a high-quality surface finish. Utilizing both wet and dry surface grinders with both manual and CNC control, Voss is able to fulfill your grinding needs. Voss prides itself on high tolerance, high precision grinding from over 50 years of tool and die experience. Our combination of equipment, knowledge and highly skilled machinists allows us the ability to create highly customized end features and profiles. With an expertise in punch grinding and form grinding, Voss has developed the capability to grind complex shapes.

Key attributes:

Max. travel: 20” x 36”

Consistently hold tolerances of ±.0002”

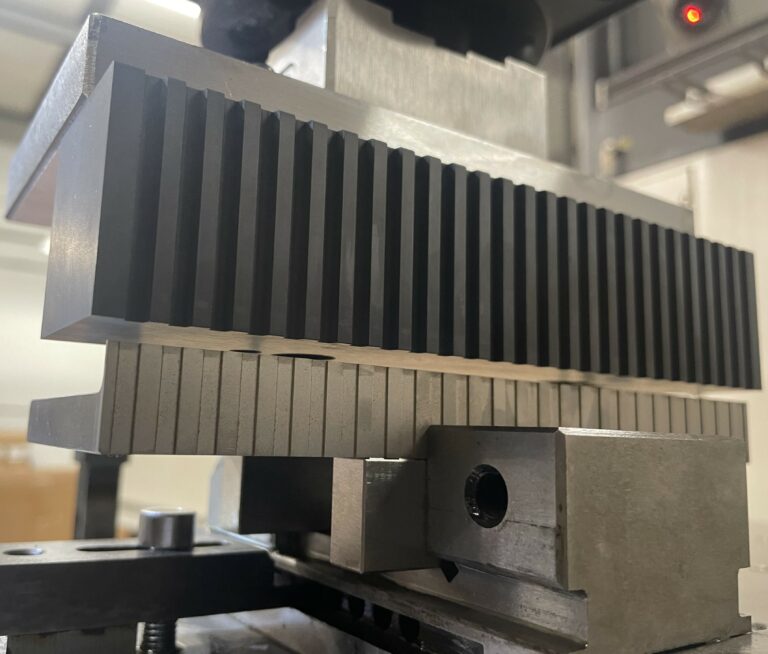

Voss offers wire EDM machining capabilities with 4 different sized Wire EDM machines along with 1 Conventional Wire EDM machine. Wire EDM is utilized for high precision parts that have intricate shapes, material stress limitations, tapers and/or surface finish requirements, all while holding tight tolerances. Wire EDM services are highly effective for use with difficult to work with materials such as hardened tool steels but is suitable for any conductive material. With the expertise of our skilled employees and our machine capabilities, Voss is able to provide wire EDM services to consistently deliver high precision and nearly perfect accuracy and repeatability.

Key attributes:

Consistently hold tolerances of ±.0002”

Maximum travel (X, Y, Z): 30” x 20” x 25”

Min. internal corner radius .003”

Taper angles up to 30°

Stand-alone operation

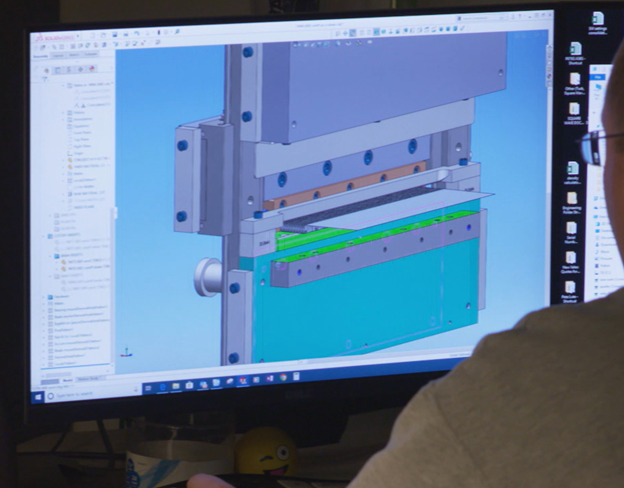

Voss rounds out their machining capabilities with 5-axis technology and the turn mill. 5-axis technology enables us to reduce setups for the machining of unique features all while holding tight tolerances. The turn mill combines milling and turning capabilities into one machine. This enables high volume automated production of components with complex geometry. These two machines allow for maximum versatility and reduction of setups as well as providing accuracy and the reduction of human error. To optimize our machine programming, Voss utilizes Mastercam software with 3D models for the most basic to extremely complex part geometries.

Key attributes:

5-axis

Max. travel (X, Y, Z, B, C): 19.69” x 17.72” x 15.75” x +110°/-5° x +/-360

Mastercam 3+2 or 5-axis contouring

Reneshaw Probe Inspection Plug

60 tool magazine

Turn Mill

9-axis machine with 5-axis contouring

10” chucks with 3” bar feed capabilities

Mastercam turn and mill up to 5-axis contouring

76 tool magazine for upper tool head with up to 20,000 RPM spindle

10 station lower turret with live tooling (allows multitasking which drastically reduces cycle times)

Reneshaw Probe Work Piece Measurement

Spindle 2 workpiece ejector and workpiece unloader

LNS QL servo bar feeder

60” turning length max

4” max turning diameter

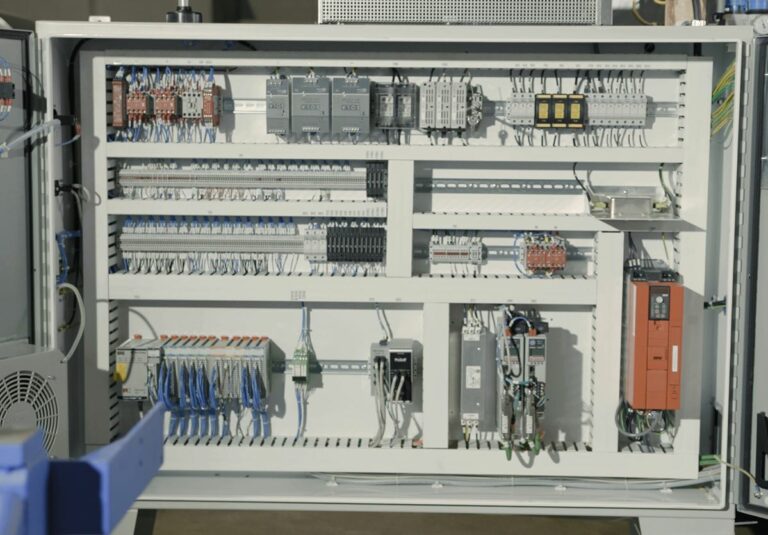

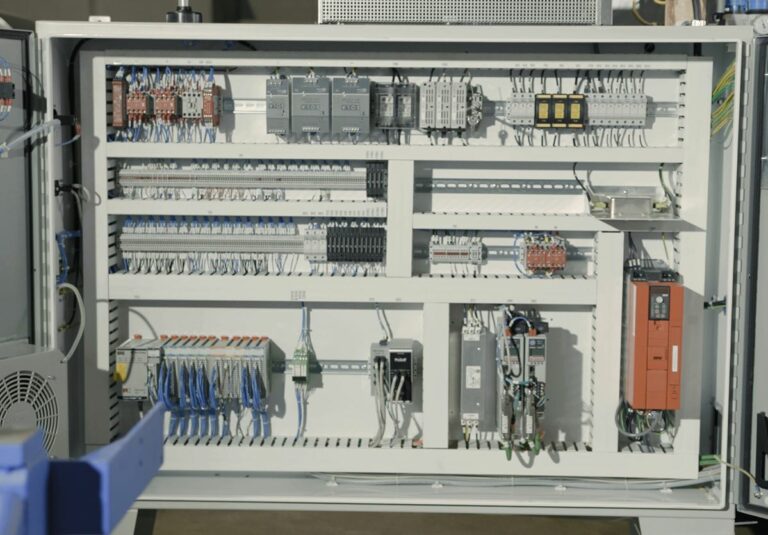

Assembly

Voss offers both mechanical and electrical assembly capabilities in our shop ranging from simple assemblies to critical high performance tooling and tooling assemblies. We are able to provide solutions for simple sheet metal panels with mounting hardware to complex automated systems (while integrating mechanical and electrical assemblies) with our highly skilled and talented assembly personnel.

Electrical Assembly & Programming

Engineering

Voss offers finishing processes for your customized parts to help improve aesthetics, rust and corrosion resistance, wear resistance, hardness or to remove burrs and other surface flaws. We are able to provide solutions from one of a kind prototypes to high production runs with our vast manufacturing capabilities and expertise.