Fin Machinery

For over 40 years, Voss has been a trusted leader in manufacturing high-quality fin production machines, delivering precision, reliability, and innovation to industries worldwide.

Our expertise in flat fin, lance offset fin, and square wave fin technology has made us the go-to partner for businesses seeking durable, high-performance solutions for their heat exchanger needs. From heavy-duty industrial applications to high-volume production environments, our machines are designed with versatility in mind—handling a wide range of materials and configurations while ensuring precise tube slotting, superior fin quality, and long-lasting durability. Let us help you build the best fins for your industry—designed for strength, built for performance, and backed by decades of experience.

Fin MACHINERY FOR MANUFACTURING

Fin & Machine Type

Partner with us for innovative manufacturing solutions tailored to your exact specifications. We deliver worldwide.

Flat Fin Types

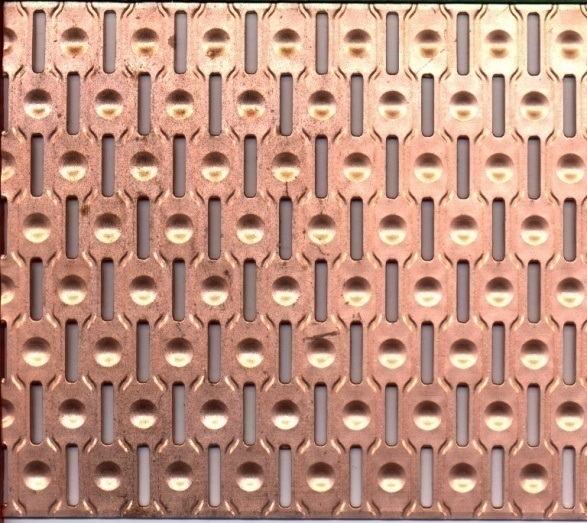

Flat or plate fins are used in the heavy-duty heat exchangers where strength of the core is important.

These fins can be made from several materials such as copper, brass, steel, or aluminum. There are hundreds of designs for this type of fin, varying the tube size, tube pitch, tube row spacing and with features such as louvers, dimples, stiffeners, that make them work for many purposes. Due to the many applications for this fin the fin material can be as thin as 38 microns to as thick as 0.25mm. Additional options to help strengthen the core face include steel or brass edges.

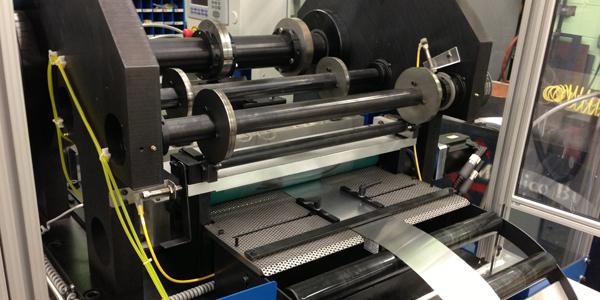

A The FM-135 is used to produce your flat or plate style fins. This machine is the smaller of the two industrial flat fin machines, (FM-135 and FM-235), with a capacity of up to 150mm wide fins.

Voss started producing fin machines almost 40 years ago and the FM-135 remains the foundation for all our stamping machines today.

This is a rock-solid Fin Machine that can be tooled up to produce almost any flat industrial type of fin you can imagine. Our library consists of hundreds of fins we’ve produced over the years. With an electronic feeder it makes the FM-135 a universal fin press allowing multiple sets of tooling to be run to produce a wide variety of fins for your production needs.

Voss continues to develop the tooling and machinery to improve fin quality; more precise tube slots for better tube to fin bond while still allowing a good tube push, working with thinner materials down to 38 microns, and louvers that are crisp and clean cut making your fins the best they can be.

The FM-235 is used to produce your larger flat or plate style fins or fins that have the need for more tooling stations. This machine is the larger of the two industrial flat fin machines, (FM-135 and FM-235), with a capacity of up to 250mm wide fins.

The larger frame and base plate allow for additional flexibility by having room for 4 die stations instead of 3, it’s able to handle fins up to 250mm wide, and has a larger drive motor to allow for heavier loads.

The FM-235 is most noted for its use in the locomotive or the heavy duty mechanical bonded radiator market, where cores can be 200mm high x 1500mm wide and up to 3m long. It’s important to have a high-quality fin for this type of radiator to ensure they assemble and perform correctly. It’s also used for setting up two-out tooling, whereas you can run high production two strips at a time in one machine. Fins up to 110mm wide can be run side by side in this machine. Flexibility, although wider and more stations, this machine can run the smaller tooling that is used in the FM-135 machine.

Voss continues to develop the tooling and machinery to improve fin quality; more precise tube slots for better tube to fin bond while still allowing a good tube push, working with thinner materials down to 38 microns, and louvers that are crisp and clean cut making your fins the best they can be.

Lance Offset Fin Types

Lance offset fins are used where higher performance is required, typically more than a square wave fin.

Main uses for lance offset fin are internal fins used in bar and plate coolers but can also be used in tube and fin construction or formed plate and fin construction. Typically, these fins can be designed for performance by changing the material thickness, fin density, lance length, and fin height. Fin thicknesses range from 0.075mm to 0.40mm, fin densities from 4 fins per inch to 32 fins per inch, heights from 1.0mm to 12.0mm and lance lengths from 1.0mm up to 25mm.

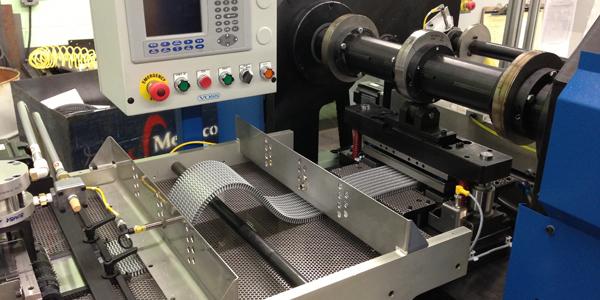

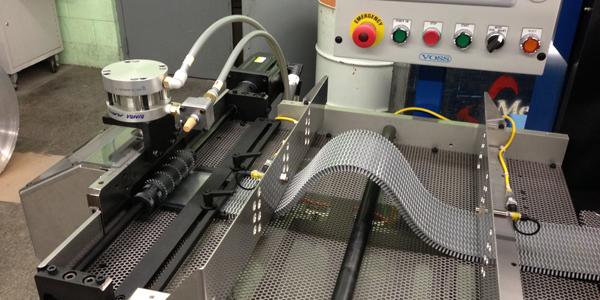

The FM-235-SW machine is used for making square wave and lance offset type fins with appropriate tooling.

This machine is narrower than the FM-335 machine, only going up to 240mm width capacity. This limits the internal turbulator to 240mm but is well suited for the narrower external fin. In some cases, two strips of external square wave fin can be run, up to 110mm wide for added production needs. For those with space limitations, or just getting into bar and plate coolers, this is the ideal machine to start with. Lower tooling costs compared to the larger FM-335 but the same quality and options available to you.

The tooling is set up to give the most accurate fin height in the industry and with the flexible servo feed system, allows for precise control over the cut width of the turb, both making sure of the best possible fit into your assembly. A heavy-duty capacity uncoiler is used to accommodate the rolls of raw material. Weight up to 350kg, widths up to 240mm and diameters up to 1m. Multiple cutoff options are available for this machine with interchangeable cutting blades that allow changing from a wavy cut to a straight cut. Blades specially made for high density fins are available, and blades for special materials such as Inconel or stainless steel are available.

With punching speeds up to 300 spm, and quick-change tooling, it will out produce all the competition by as much as 4x and have a tooling changeover in just 20 minutes. A variable speed drive to control the punching speed is also available as some tools you may want to run a bit slower to match up with production, or some tools faster as you are stockpiling the fins. Either way you can dial in the speed that best suits your needs with this option.

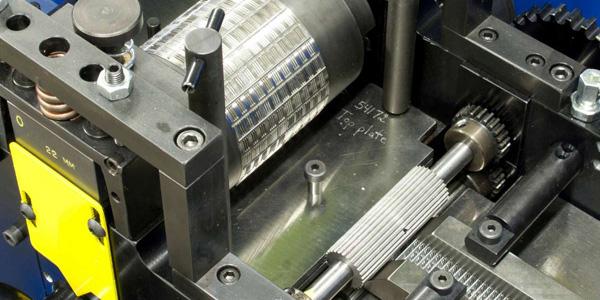

The FM-335 machine is used for making square wave and lance offset type fins with appropriate tooling.

This machine is the most robust machine that Voss produces in terms of tonnage and strip width capacity. Intended for full OE production of internal and external fins used in bar and plate type coolers, the added width can also handle multiple fin strips being run for added production speed on narrower fins.

The tooling is set up to give the most accurate fin height in the industry and with the flexible servo feed system, allows for precise control over the cut width of the turb, both making sure of the best possible fit into your assembly.

A large capacity uncoiler is used to accommodate the larger rolls of raw material accommodating a larger diameter, width, and weight. Standard tooling produces flow lengths (material widths) up to 450mm, while wide tooling produces flow lengths (material widths) up to 495mm. Multiple cutoff options are available for this machine with interchangeable cutting blades that allow changing from a wavy cut to a straight cut. Blades specially made for high density fins are available, and blades for special materials such as Inconel or stainless steel are available.

With punching speeds up to 300 spm, and quick-change tooling, it will out produce all the competition by as much as 4x and have a tooling changeover in just 20 minutes.

Square Wave Fin Types

Square wave fins are used primarily in bar and plate coolers and tube and fin coolers, where a strong open fin is required for the application such as charge air coolers, radiator, oil coolers or EGR coolers. The square top helps to give excellent tube to fin bond, with the square shape allowing maximum air or fluid flow. The wave shape, either serpentine, herringbone or straight allow you to dial in the performance needed. These fins can be made from several materials such as copper, brass, steel, or aluminum.

The FM-235-SW machine is used for making square wave and lance offset type fins with appropriate tooling.

This machine is narrower than the FM-335 machine, only going up to 240mm width capacity. This limits the internal turbulator to 240mm but is well suited for the narrower external fin. In some cases, two strips of external square wave fin can be run, up to 110mm wide for added production needs. For those with space limitations, or just getting into bar and plate coolers, this is the ideal machine to start with. Lower tooling costs compared to the larger FM-335 but the same quality and options available to you.

The tooling is set up to give the most accurate fin height in the industry and with the flexible servo feed system, allows for precise control over the cut width of the turb, both making sure of the best possible fit into your assembly. A heavy-duty capacity uncoiler is used to accommodate the rolls of raw material. Weight up to 350kg, widths up to 240mm and diameters up to 1m. Multiple cutoff options are available for this machine with interchangeable cutting blades that allow changing from a wavy cut to a straight cut. Blades specially made for high density fins are available, and blades for special materials such as Inconel or stainless steel are available.

With punching speeds up to 300 spm, and quick-change tooling, it will out produce all the competition by as much as 4x and have a tooling changeover in just 20 minutes. A variable speed drive to control the punching speed is also available as some tools you may want to run a bit slower to match up with production, or some tools faster as you are stockpiling the fins. Either way you can dial in the speed that best suits your needs with this option.

The FM-335 machine is used for making square wave and lance offset type fins with appropriate tooling.

This machine is the most robust machine that Voss produces in terms of tonnage and strip width capacity. Intended for full OE production of internal and external fins used in bar and plate type coolers, the added width can also handle multiple fin strips being run for added production speed on narrower fins.

The tooling is set up to give the most accurate fin height in the industry and with the flexible servo feed system, allows for precise control over the cut width of the turb, both making sure of the best possible fit into your assembly.

A large capacity uncoiler is used to accommodate the larger rolls of raw material accommodating a larger diameter, width, and weight. Standard tooling produces flow lengths (material widths) up to 450mm, while wide tooling produces flow lengths (material widths) up to 495mm. Multiple cutoff options are available for this machine with interchangeable cutting blades that allow changing from a wavy cut to a straight cut. Blades specially made for high density fins are available, and blades for special materials such as Inconel or stainless steel are available.

With punching speeds up to 300 spm, and quick-change tooling, it will out produce all the competition by as much as 4x and have a tooling changeover in just 20 minutes.

Round Tube Fin Types

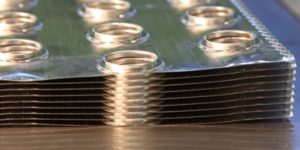

Round tube fins are similar to Flat fins with the exception that the tube is round and are typically used for heavy duty applications where high pressure is required such as on condensers, oil coolers, radiators, and refrigeration. These fins can be made from several materials such as copper, brass, steel, or aluminum. Round tube fins are stamped, and can have different features such as louvers, waves, or dimples. Design criteria normally include the tube size, pitch and row spacing along with enhancements required.

Voss produces fin machinery for round tube fins such as this FM-235-RT Machine.

Unlike the typical drawn cup type tooling, this tooling uses a simplified version to produce the fin collar. Just a pierced hole, then flanged, with a small re-flare is what’s used to produce the fin, keeping the tooling costs down. This process allows manufacturers to get into this marketplace with less investment or prototype new fins with lower tooling costs. The machine is based on the FM-235 flat fin machine except for the feed station, which is moved over to allow more stations needed to produce the fin. This allows for enhancements such as waves, louvers, or dimples to be used in conjunction with the tube collar tooling.

Serpentine Fin Types

Serpentine fins are roll formed fins used in a variety of heat exchangers such as radiators, condensers, evaporators, charge air coolers, or oil coolers. These fins can be made from several materials such as aluminum, copper, brass, or steel. They normally have a louver pattern, but can be made with dimples, or just as plain fin. The typical fin height ranges from 6mm to 12mm.

The RF-220 fin machine model produces a serpentine fin. Serpentine Fins are a corrugated type of fin, usually louvered or ribbed, made of copper, brass, or aluminum, and used in the automotive and light industrial markets.

The base machine can accommodate 3 sizes of tooling, fin widths of 100mm, 150mm and 200mm wide, based on the tooling purchased. Two types of tools are available, one that uses the Voss patented Pin-Roll, and one that doesn’t. The patented Pin-Roll design gives the fins a few advantages over the other types of tooling such as: a slightly tighter tip radius, increases compression strength of the fin and decreases fatigue failure of the tip radius. The other type of tool gives a larger tip radius giving you added braze joint material, more of an upright leg on the fin, slightly larger opening, and more forgiving on the core compression stack height. Both tool options give you better louver angle consistency, with this design there is no need for phasing the upper and lower rolls for louver angle shift, these rolls are always in phase and therefore have very consistent louver angles.

A quick-change tooling system allows changing fin heads in just a couple minutes. Inline slitting is available for high volume production, whereas one strip enters the machine and two finished fins come out doubling your production on one tool. A fin finder cutoff system is used on most systems to cut in the valley of the fin each time.

Max Fin Length – 60” [1500mm] (Determined by boom assembly capacity)

Parts per Minute – 30 max, depending on fin density and cut length

Ready to talk about your manufacturing needs?

Give us a call to schedule your consultation today.