Assembly Machines

For over 40 years, Voss has been a trusted leader in manufacturing high-quality fin production machines, delivering precision, reliability, and innovation to industries worldwide.

Our expertise in flat fin, lance offset fin, and square wave fin technology has made us the go-to partner for businesses seeking durable, high-performance solutions for their heat exchanger needs. From heavy-duty industrial applications to high-volume production environments, our machines are designed with versatility in mind—handling a wide range of materials and configurations while ensuring precise tube slotting, superior fin quality, and long-lasting durability. Let us help you build the best fins for your industry—designed for strength, built for performance, and backed by decades of experience.

Custom ASSEMBLY MACHINERY FOR MANUFACTURING

Assembly Machine Types

Partner with us for innovative manufacturing solutions tailored to your exact specifications. We deliver worldwide.

CNC Header Press

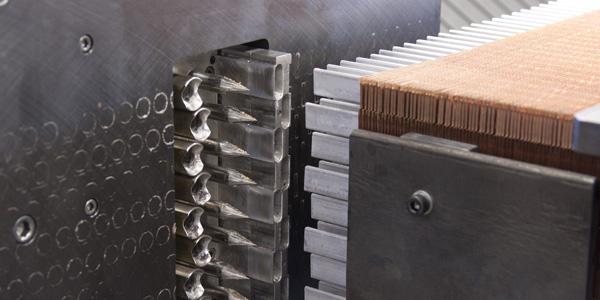

This machine is specifically designed to punch bolt-on type header plates with the use of its 8-station tool changer and custom Voss software used to program your header plates. Add Voss tooling to the system and you can produce header plates of the highest quality required by your demanding applications.

The machine uses a unique triple action system to punch the header plates, controlling each the punch, die and stripper holding pressure mechanically to produce superior tube slots. Some deep draw applications can produce collars that are up to 4mm high in 1.6mm material. These machines are simple to program and easy to run with minimum training.

Custom header tooling is available on request. The process used on the HP-600 lends itself to be used for developing / testing new tube slot geometry at very economical prices. Only one slot or feature is being punched at a time making it the perfect machine to use for your development.

Header tooling, in particular the geometry of the tube slot, is so important to the fit and function of a tube to header joint. Voss can develop for you custom geometry to optimize this joint based on your requirements. Currently, tube slots for radiators and CAC cores are quite often developed on this machine prior to getting production tooling made to save time and money.

The Voss HP-600 CNC Header Press is used to produce Industrial bolt-on type header plates.

Voss has developed a method for brass headers to create a deep draw extrusion that has proven to be superior to normal brass tube slots, and often competes with welded joints. The long extrusion gives the much-needed contact between the tube and header for a very strong, long-lasting, leak free joint.

Serpentine Assembly Fixtures

These fixtures are used for all your heat exchanger and core building needs. Voss offers a variety of assembly fixtures depending on the size and construction of your core.

These fixtures are used to build smaller size heat exchangers which are tube and fin construction. The core is built in layers: tube, fin, tube, etc. until the stack height is reached. Once assembled, the core is compressed with a small cylinder from the bottom upward against a set of stop pins. This ensures the core is compressed square and to the proper height required. The fixture features side channels that retract out of the way for easy core removal and dedicated pressure gages to control the compression pressures. Simple flexible design allows building of most any smaller heat exchanger that uses a stacked design.

These fixtures are used to build medium size heat exchangers which are tube and fin construction. The core is built in layers, tube, fin, tube, etc. until the stack height is reached. Once assembled, the core is compressed with two large cylinders from the bottom upward against a set of stop pins. This ensures the core is compressed square and to the proper height required. The fixture features side channels that independently retract out of the way for easy core removal and dedicated pressure gages to control the compression pressures. Simple flexible design allows building of most any medium sized heat exchanger that uses a stacked design.

These heavy-duty assembly fixtures are used for bar and plate type core building where there needs to be high pressure to compress the core prior to banding. The heavy-duty construction allows these pressures to be distributed evenly on the core without distortion. It features two large bore cylinders mounted on the top for compression. Movable side guides are used to keep the core square during building.

These heavy-duty tilting fixtures are used for building large-stacked core heat exchangers such as locomotive, or gen-set type cores. Serpentine fins or square wave fins can be used with core depths up to 150mm and tube lengths up to 3m long. Featuring hydraulic compression, a tilting table and roller bed, these fixtures are a must have for large core production.

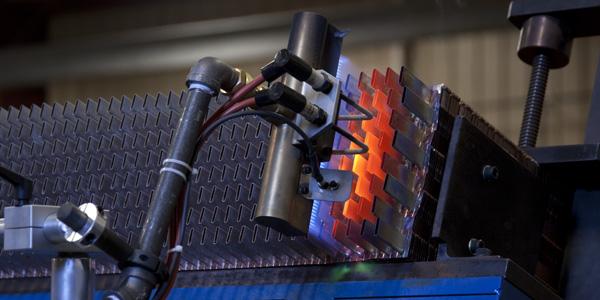

Auto Core Builder

The ACB-8090 is perfect for building those large radiators typically used in standby of full-service generators. This machine uses an integrated fin machine and tube escapement to aid in building these cores with minimal part handling. The core is built from the top down as the fin machine produces the fin, feeds it into the core builder where it’s placed on the last row of tubes and then after the fin is in place the tubes are dropped on the top and the cycle is repeated.

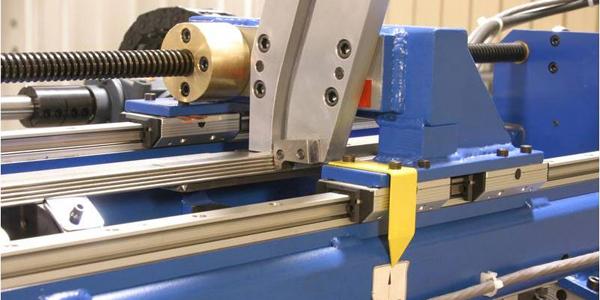

Semi-Automatic Tube Pushing Machine

This Semi-Auto Tube Pusher is used for assisting the operator pushing tubes on long cores up to 3m. It’s hard to handle tubes this long manually, so having a machine guide and push them is beneficial not only to the operator but to be able to produce a tighter fitting tube for better performing cores. Connected to an assembly fixture it’s a perfect match for building these large cores that are used in the locomotive industry and large gen-set type radiators. Programming is easy and can be adapted to your fin pattern. Different tube guides are available for use with your tube sizes.

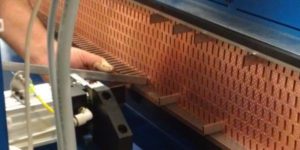

Semi-Automatic Tube Stuffing Machine (TS-60)

The Semi-Automatic Tube Stuffing Machine is used to insert the internal fin into a welded tube usually used in CAC Coolers. This is a semi-auto machine where the operator places a fin to be inserted on the table and initiates the cycle start actuating the machine to compress and insert the fin into the tube.

Core Squaring Fixture

The Core Squaring Fixture is used to square large cores after baking to ensure the tube ends are flush with one another and square to the core edge. These are mostly used in mechanical bonded type cores where the tube end position is important, but they can also be with normal industrial type radiator cores. Once the core comes out of the baking oven, it’s loaded into this fixture, secured along the edge, and a ram from the tube end pushes the core against a fixed stop. This evens up the tube ends, and squares the warm core, then the core is left to cool in the fixture.

Transform Machine

The Transform Machine rounds out our line of machinery used for mechanical bonded type radiator manufacturing.

Ready to talk about your manufacturing needs?

Give us a call to schedule your consultation today.