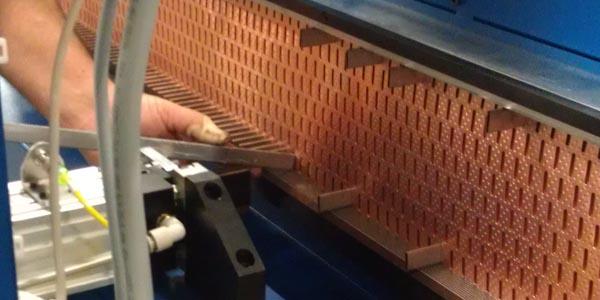

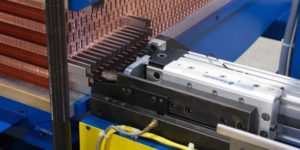

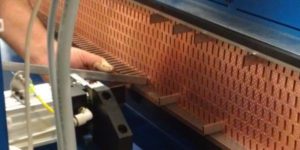

This Semi-Auto Tube Pusher is used for assisting the operator pushing tubes on long cores up to 3m. It’s hard to handle tubes this long manually, so having a machine guide and push them is beneficial not only to the operator but to be able to produce a tighter fitting tube for better performing cores. Connected to an assembly fixture it’s a perfect match for building these large cores that are used in the locomotive industry and large gen-set type radiators. Programming is easy and can be adapted to your fin pattern. Different tube guides are available for use with your tube sizes.

Semi-Automatic Tube Pushing Machine (TP-63120)

Specification

- Machine Size – 15ft [4.5m] W x 7.5ft [2.3m] L x 5.5ft [1.60m] H

- Machine Weight – 3300 lb. [1500 kg]

Capacity

- X Travel (Max Fin Length) – 63″ [1600mm]

- Y Travel (Mac Core Thickness) – 8” [200mm]

- Z travel – (Max Tube Length) – 120″ [3050mm]