The Transform Machine rounds out our line of machinery used for mechanical bonded type radiator manufacturing.

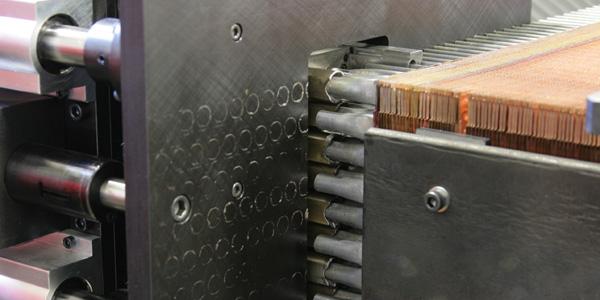

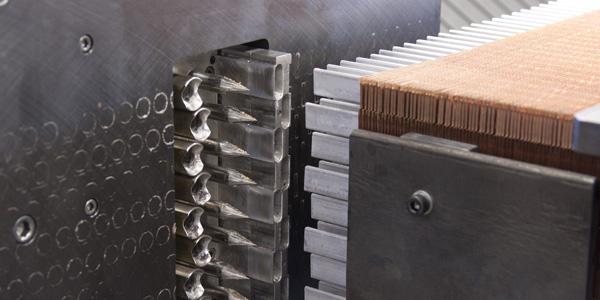

Mechanical bonded type radiators are made like industrial radiators with the exception of; the headers are made from 16mm thick steel plate. The tubes are rounded on the ends to be mechanically bonded to the header plate.

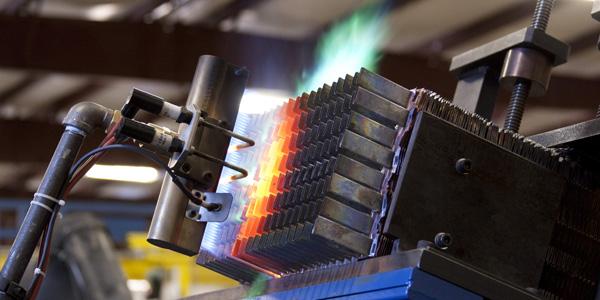

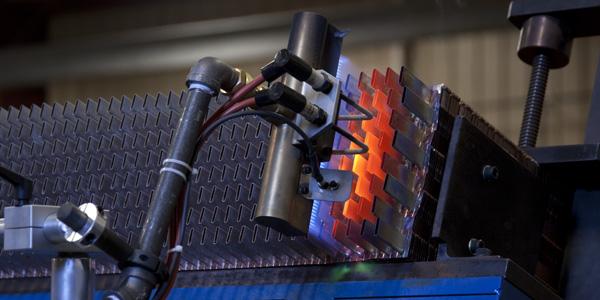

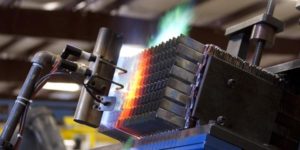

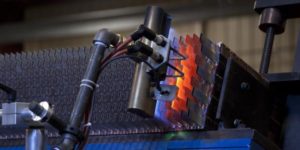

This machine is used to transform the tubes from oval to round after the core is baked. The process involves annealing the tube ends first, then transforming them from the oval shape to a round shape to fit into the round header plate hole to be mechanically bonded together. These types of cores are superior in the industry due to their heavy-duty nature and tube to header bond.

Transform Machine (TF-63120)

Specification

- Machine Size – 16ft [5.00m] W x 8ft [2.50m] L x 8ft [2.50m] H

- Machine Weight – 3500 lb. [1600 kg]

- Machine Speed – 12 in/min [300mm/min] (annealing)

- Transforming Speed – 10 sec/stroke

- Transforming Operation – Servo Controlled

- Machine Power – 400/460 VAC, 3 PH, 50/60 HZ, 40 AMP

- Air Supply – 100 psi Moisture Free Air

- Gas Supply – Propane or natural gas

Capacity

- Max Fin Length – 63″ [1600mm]

- Min Fin Length – 6″ [150mm]

- Max Tube Length – 120″ [3050mm]

- Min Tube Length – 20″ [500mm]

- Max Core Thickness – 8″ [200mm]